SOLAR THERMAL APPLICATIONS UNIT

Soluciones termosolares para integración en procesos industriales (SOLTERMIN)

Participants: CIEMAT

Contact: Loreto Valenzuela, loreto.valenzuela@psa.es;;

Ángel Morales, angel.morales@ciemat.es

Funding agency: MINECO –Retos Investigación 2017: Proyectos I+D+i (Ref. ENE2017-83973-R) (Jan. 2018 – Jun. 2022)

Background: Commercial deployment of concentrating solar thermal (CST) technologies has grown significantly, with about 5GWe of installed capacity worldwide for electricity generation. However, the commercial use of concentrated solar thermal energy is still very limited, despite the fact that more than 66% of total energy consumption in the industrial sector is dedicated to industrial heat processes.

Objectives: The project SOLTERMIN aims to advance in the development of new components and solutions to facilitate the integration of concentrated solar thermal technologies as thermal energy provider in industrial processes, with the following objectives:

- Development of an innovative linear Fresnel solar collector (iLFC) for its integration in industries, including the development of a lightweight and optimized primary concentrator design to reduce optical losses and the development of an absorber coating valid up to 400°C and stable in air.

- Research on solar components for tower systems devoted to industrial process applications, including innovative and optimized heliostat designs and volumetric air receivers.

- Study of the durability and reliability of solar reflectors installed in industrial environments.

- Integration of linear Fresnel solar systems in different industrial processes: a) from a food and drink industry; and b) multi-effect distillation (MED) plant with steam ejectors. And integration of a solar tower system coupled to a Brayton cycle and a MED plant.

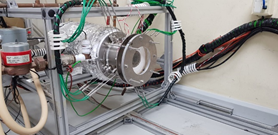

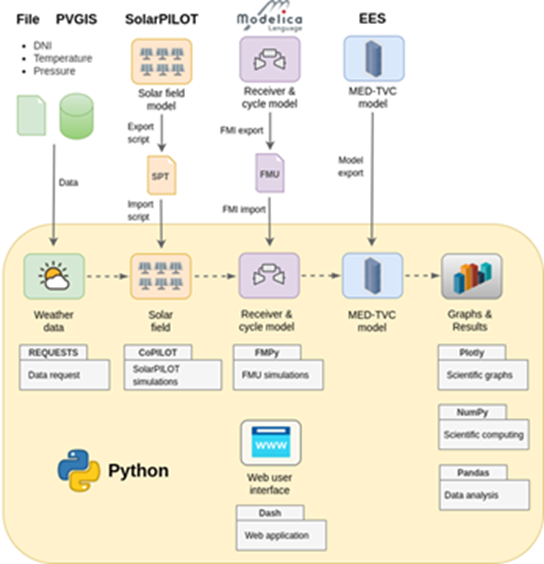

Achievements in 2018: The design of the multi-tube receiver for the first prototype of an innovative linear Fresnel collector has been completed. This year, materials were gathered for the construction of the trapezoidal cavity designed for the receiver (aluminium mirrors, aluminium for the frame, heat insulation, solar glass windows, etc.). A preliminary CFD simulation model of the receiver has been developed and a parametric study on its thermal behaviour was carried out to estimate the heat losses in the receiver. On the other hand, the electronic control for the primary concentrator of the LFC prototype was installed. Both, the results of the CFD simulation of the receiver and the characteristics of the control system designed and installed, were presented in two separate presentations at the SolarPACES 2021 conference. The development of a selective coating stable in air for medium temperature applications was completed (absorptance > 0.95 and emittance@350°C < 0.10); the durability of the coating was also completed with no degradation of the optical properties observed after 15 months of testing. A new selective coating for high temperature (700°C) applications was also developed with a solar absorptance of 0.95 and a thermal emittance at 700°C of 0.20. Thermal stability after 2 months at 700°C was not affected. The antireflective coating developed to be applied on the receiver quartz window has been optimized. The quartz solar transmittance value was increased from 0.93 to 0.98 after its application. The durability of these coatings was studied by abrasion tests with a linear abrasive tester and a sand oscillating device. All the results showed that more resistant coatings are obtained when using sintering temperatures around 700°C without decreasing the high solar transmittance values. Laboratory developed prototypes were tested in a 7-kW solar simulator observing no degradation of the windows after testing (Figure 1). With CFD software, a parametrical study about the thermal and hydrodynamic influence of the absorber’s physical design within a standard cup were comprehensively analysed and the results were presented in SolarPACES 2021. Moreover, a detailed analysis of the heat transfer coefficient in wire mesh volumetric receivers was carried out and the main conclusions were presented in SolarPACES 2021, ISES 2021 and 1st ARE. With simulation models developed in TRNSYS, the integration of iLFC-solar fields in two industrial processes: pasteurization and brewing, was simulated. The studies included performance comparisons to flat-plate collectors. A preliminary economic analysis suggests that the iLFC concept may achieve lower values of Levelized Cost of Heat that other technologies when the cost of industrial land is higher than 60 €/m2. The results were presented at the SolarPACES 2021 conference. Regarding Task 4.3, a comparison in terms of energy efficiency and water production of two solar cogeneration plants was performed. The solar cogeneration plant consists on a Central Receiver CSP plant with a combined cycle formed by a solar-hybrid gas turbine system plus a Rankine steam cycle and two integrated desalination systems: 1) a low-temperature multi-effect distillation (LT-MED) unit and 2) a reverse osmosis unit. The results were presented in ICP 2021 “Sixth International Conference on Polygeneration” and the paper was selected to be sent to a Special Issue of Energy Journal. Also, the development of an heliostat field model in SolarPILOT and central receiver system in Modelica has been carried out, coupling together with the previous developed Brayton cycle model and online input data to simulate the system and generate interactive results on a web app which is currently under development (https://soltermin.herokuapp.com) (see Figure 2).