Porous media laboratory for solar concentrating systems - POMELAB

The porous media laboratory located in CIEMAT-Moncloa (Madrid) comprises three main facilities, and some other techniques for the characterization of porous materials used for central receiver systems with air as heat transfer fluid.

1) Thermal characterization of volumetric absorbers

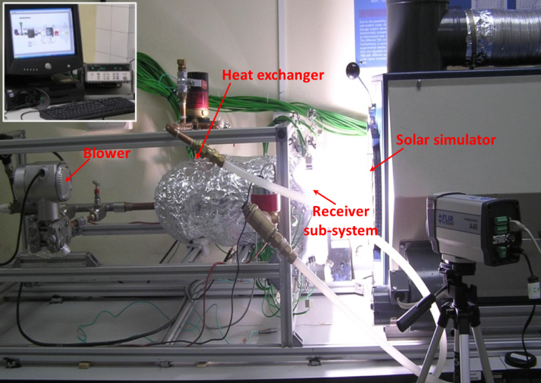

Its main component is a test bench designed for the thermal test of new volumetric absorbers and configurations and its ageing in steady and dynamic conditions. The main components installed in this test bench are:

- A 4 kWe solar simulator made up of a Xenon lamp and a parabolic concentrator that can reach fluxes of up to 1500 kW/m2;

- Receiver sub-system: with 24 K-type thermocouples, 2 surface thermocouples and an infrared camera;

- Helicoidal Air-Water Heat Exchanger sub-system: with 4 PT100 sensors, a water mass flow-rate measurement, a water pump and 2 surface thermocouples; and

- Extraction system: with 1 k-type thermocouple, 1 PT100 sensor, an air mass flow-rate measurement, and an air blower.

This test bench has the flexibility to study the extinction coefficient of different mediums, which can be used as a tool to approximate radiation analysis in semi-transparent mediums following the Bouger’s law.

2) Thermal evaluation of porous beds in regenerative systems

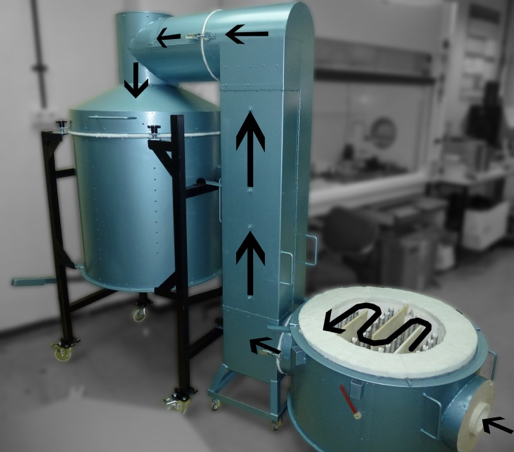

Previous facility is complemented by an indoor facility to study thermal storage materials for high temperature using air as heat transfer fluid. This facility is composed of a thermocline storage test bench of about 0.1 m3 as experimental loop for static and dynamic thermal characterization of porous beds. The system consists of:

- Six power heating resistor with a total power of 15000 watts electric energy able to heat air up to a target temperature (maximum temperature limited by the resistor is 1000°C) by means of a temperature controller.

- 35 K-type thermocouples units of 400 mm long are used to measure the material temperature. The behaviour of the tank is measured at 7 levels with 5 measurement each level.

- 35 T-type thermocouples units are used to measure the vessel outlet temperature in order to calculate thermal losses to the environment.

- The total power consumption is recorded, with a three-phase electrical measurement, to match the energy balances and the heat losses.

Moreover, the external surface temperature mapping is registered by a thermograph camera, which offers a complete image of the external chassis of the tank.

The two possible configurations of this test bench are:

- Static configuration: the experimental loop allows the characterization of effective thermo-physical parameters of the bed; material thermal conductivity, thermal losses, stored energy, etc. for different filler materials.

- Dynamic configuration: the experimental loop allows an agile characterization of the global storage at different working temperatures, filler materials, charges and discharges strategies, etc.

3) Measurement of the pressure drop up to 300°C

This facility measures the pressure difference across porous materials, such as volumetric absorbers or filler materials, for different fluid velocities. Moreover, it is able to measure the pressure difference at ambient temperature and for air temperatures up to 300°C.

Then the main properties described by the Forchheimer extension to Darcy’s law are derived: viscous permeability coefficient and, inertial permeability coefficient. The main components are:

- Sodeca Blower with velocity control

- Hastinik ball valve of 1 ½ʺ.

- Airflow anemometer

- Nabertherm heating resistor

- Honeywell pressure difference-meter

Moreover, different techniques have been developed for the evaluation and measurement of several important geometric parameters of porous materials such as the porosity and specific surface area.