POINT-FOCUS CONCENTRATING SOLAR THERMAL TECHNOLOGIES

AVANSOL Advanced volumetric absorbers for high-concentrating so-lar technologies

Participants: Solucar, Coordinator; Fundación INASMET, Univ. Seville and CIEMAT [three Divisions:

- a) CIEMAT-PSA,

- b) CIEMAT- Fusion Materials. National Fusion Laboratory;

- c) CIEMAT- Structural Materials Division].

Contacts: Cristina Montero (cristina.montero@solucarrd.abengoa.com); Félix M. Téllez (felix.tellez@ciemat.es)

Duration: October 30, 2005 – October 30, 2007 (extended to June 2008)

Background: After experiments with about thirty different-sized volumetric receiver prototypes, there are still matters pending that are crucial to the development and industrial application of this type of receiver: i) Durability of materials; ii) Efficiencies observed in volumetric receivers up to now are far from expected performances, the apparent temperatures are similar to maximums and thermal behavior does not adequately reproduce theoretical models; iii) determination of optimum pretreatment techniques of porous materials such as “blackening” for operation at high fluxes and high temperatures; iv) Search for new materials and geometric structures which would allow low-cost thermal performance; v) Scale-up of receiver sizes to around 50 MWth or higher.

Purpose: The AVANSOL project attempts to respond to two main uncertainties in air-receiver technologies: 1) Durability of the volumetric receiver under real operating conditions, and 2) Optimum selection of absorber material and porous geometry. An advanced metal volumetric absorber and another ceramic one (with higher efficiencies, durability and lower-cost) for high-temperature applications between 600 and 800ºC (metal) and between 800 and 1000ºC (the ceramic absorber prototype) were developed to do this.

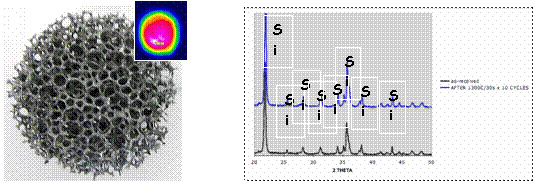

Achievements in 2007: In 2007, a series of samples of porous ceramic structures were made at the University of Seville and the INASMET Company, to test the adaptability of a variety of porous structure manufacturing methods to the requirement for gradual porosity of volumetric receivers. Many of these test pieces were tested under thermal shock and cycled with very high solar flux thanks to French acceptance of the proposal for testing in the CNRS furnace in Odeillo.

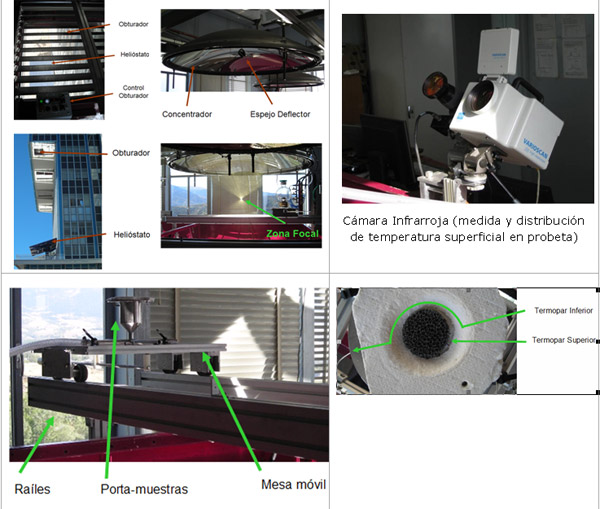

Furthermore, new experimental capacities partly funded by this project were installed and characterized:

- i) 4000 W lamp for lab tests between 100 and 1500 kW/m2;

- ii) optical bench for measuring reflectivity and directional transmissivity of porous absorbers;

- iii) device for testing solar thermal cycling to be installed in a parabolic dish at the Plataforma Solar de Almería; iv) acquisition and adjustment of Vickers and Knoop (Leco mod LV-700) hardness tester; v) acquisition and adjustment of thermogravimetric and thermobalance analysis system.